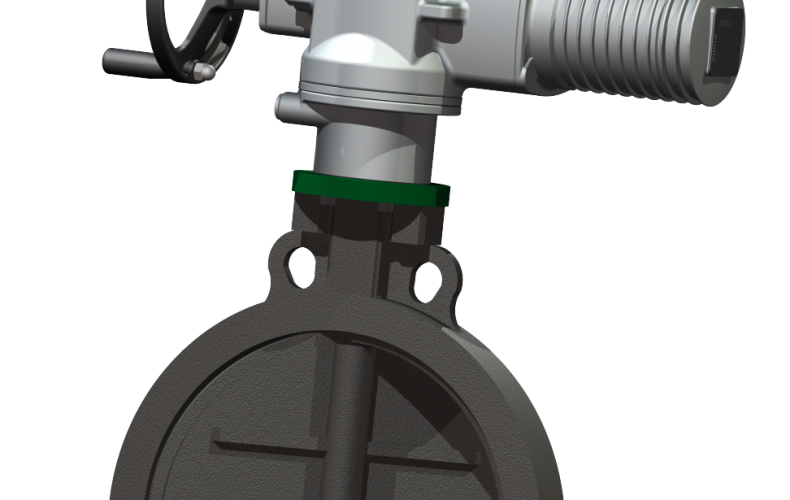

LINA is specially designed for ventilation systems in accordance with the DIN 24154 standard. Despite its lightweight and compact design, we were very careful that it be able to fully satisfy the extreme demands placed on it in industrial applications. Adjusting for the combination of materials, LINA can be employed to safely handle regulate extreme parameters (high temperatures, aggressive media, etc). Owing to its modular welded design, we can quickly and accurately modify LINA to your specific application. Like all our valves, LINA also has an integrated ISO interface, and comes with corrosion protection right out of the box.

Other advantages LINA offers:

- Sealing Classes I, II, III per FCI 70-2 1976 (R1982) or better.

- Sealing air model provides for 100% air-tight seal.

- Class I optimized for dust-laden media

- Fire-resistant lining available (refractory concrete, fireproof mineral wool).

- Flange valve with flanges according to DIN 24154 standard

- Special dimensions available upon request.

- DN 40 to DN 2000 (other sizes available separately).

- For air, flue gas, waste gas.

- Operating temperatures up to 1050°C.

- Low torque due to „low-friction packing.“

- Integrated ISO 5211 interfaces.

- Conversion kit available for easy, subsequent LINA automation.

- Corrosion protection included in the standard model.

- Actuation by hand lever, worm drive, electric, pneumatic, hydraulic

- 100% air-tight