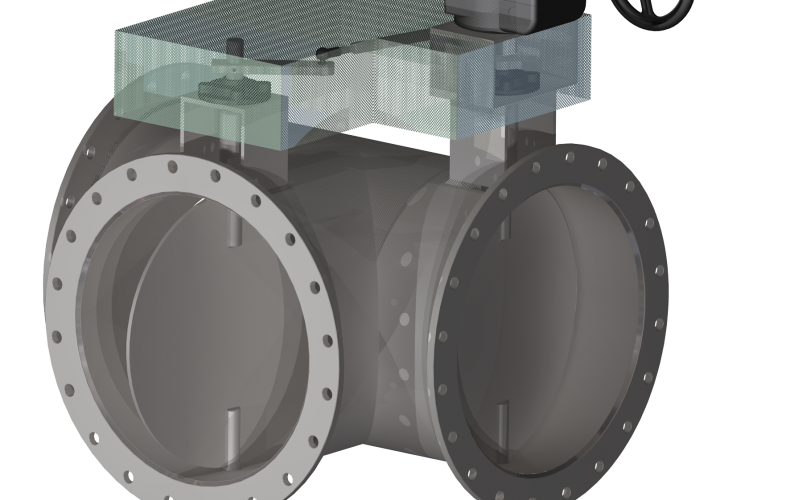

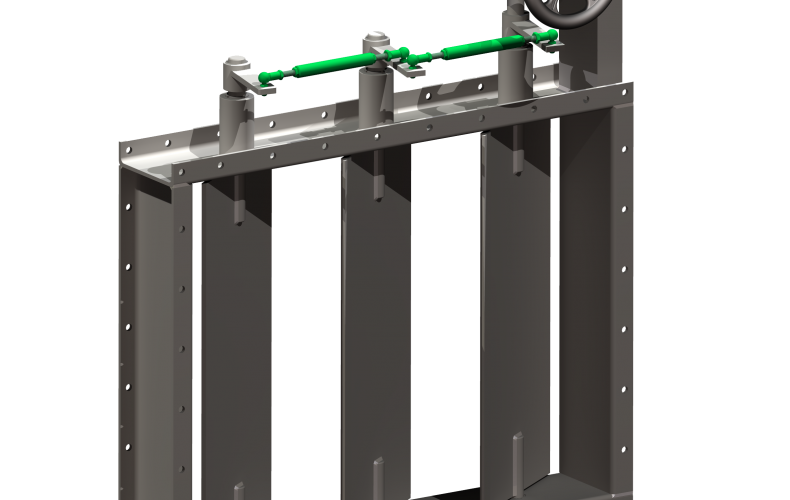

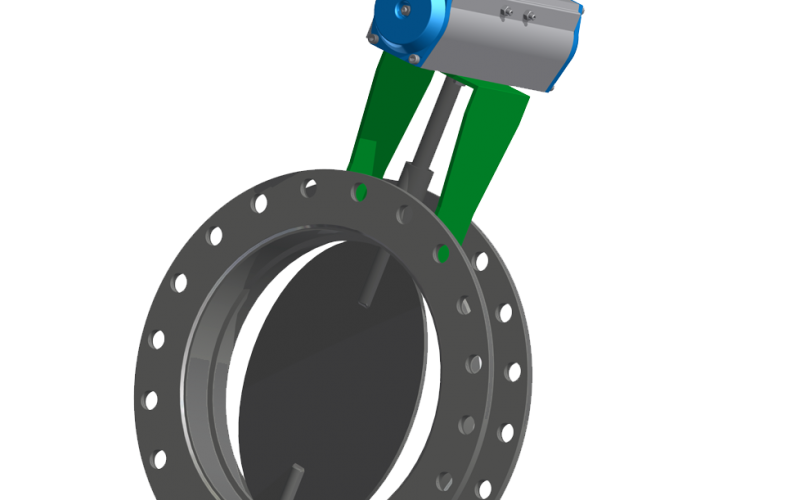

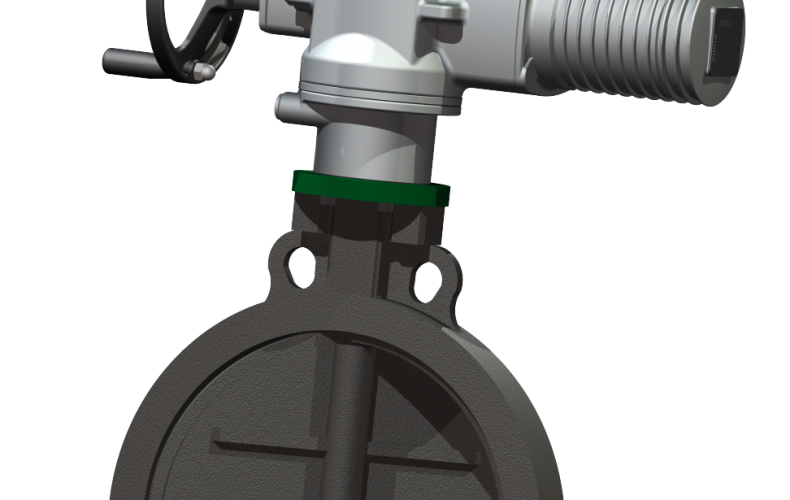

RIA is specially designed for use for flue and exhaust gases up to 1100°C. Depending on specifications, we can supply RIA in various, ready-made configurations, or we can adapt it to precisely suit your specific needs. RIA has an Integrated ISO interface. This allows for direct mounting without the need for an additional console – which means the RIA can be automated quickly and easily later on. RIA is very robust, durable and requires little maintenance. With its safe and proven design, RIA guarantees high system availability even under extreme conditions.

Other advantages RIA offers:

Sealing Classes I, II, III per FCI 70-2 1976 (R1982) or better.

Class I optimized for dust-laden media

Wafer valve can be mounted between flanges per DIN or ANSI

DIN EN 1092-1 | PN 6 | PN 10 | PN-16

ANSI 150 lbs | 300 lbs | 400 lbs.

DN 40 to DN 2000 (other sizes available separately).

For flue gas, exhaust gas and air

Operating temperatures up to 1100 ° C.

Low torque due to „low-friction packing.“

Integrated ISO 5211 interface.

Conversion kit available for easy subsequent RIA automation.

Corrosion protection included in standard model.

Actuation by hand lever, worm drive, electric, pneumatic, hydraulic

100% air tight