- By Knippenburg Armaturen

- March 22, 2016

Absperrklappen

> Antriebe & Zubehör

> Buntmetallarmaturen

> Customized Solutions

> Druckminderer/-regler

> Edelstahlarmaturen

> Fernwärmekugelhähne

> Filter

> Hochdruckventile/-schieber

> Kompensatoren

> Kondensatableiter

> Kugelhähne

> Magnetventile

> Mano-/Thermometer

> Membranventile

> Regelarmaturen

> Rückschlagarmaturen

> Schaugläser

> Schieber

> Schmutzfänger

> Schweißkonstruktionen

> Service:

> Gegenflansche, Schrauben und Dichtungen

> Sicherheitsventile

> Stoffschieber

> Strangregulierventile

> Ventile

- By Knippenburg Armaturen

- March 22, 2016

Ausführung

Wafer, LUG, Monoflansch, Doppelflansch

Betätigung

elektrisch, pneumatisch, Getriebe, Hand

Nennweiten

50 – 2000

Druckstufen

PN 25

Gehäuse

GG-25, GGG-40, AISI304, AISI316

Scheibe

GGG-40, Alu-Bronze, AISI316

Anstrich

Epoxy, Rilsan,

Welle

AISI420, AISI316

Dichtring

EPDM, NBR, Silikon, Viton, PTFE, U-PVC

Temperatur

max. 200°C

Einbaunorm

PN10/16, ANSI Class 150

Normen

EN-558 Serie 20 (DIN3202-K1), ISO5752, API609, BS5155

Prüfungen

EN12266-1/2, ISO5208, API598, ANSI B16-104, Class VI

- By Knippenburg Armaturen

- March 22, 2016

Betätigung

elektrisch, pneumatisch, Getriebe, Hand

Nennweiten

DN 8 – DN 1000

Druckstufen

PN6, 10, 25, 40, 63, 100

Ausführung

2-Wege, 3-Wege, Monoblock, Short-Pattern Design

Werkstoffe

AISI316, Messing vernickelt,AISI304, A216 WCB, U-PVC

Temperatur

-40°C bis +260°C

Einbaunorm

PN10/16, PN-25, ANSI Class 150/300

Anschlussart

Innengewinde, Anschweißenden, Flanschen,

Prüfungen

ATEX, Fire safe, DVGW, DGRL, TA-Luft

Sonstiges

Antistatik Design, Bureau Veritas getestet, ISO-Mounting Pad

- By Knippenburg Armaturen

- March 22, 2016

Ausführung:

Wafer, LUG, Monoflansch, Doppelflansch

Betätigung

Elektrisch, pneumatisch, Getriebe, Hand

Nennweiten

50 – 2000

Druckstufen

PN 25

Gehäuse

GG-25, GGG-40, AISI304, AISI316

Scheibe

GGG-40, Alu-Bronze, AISI316

Anstrich

Epoxy, Rilsan,

Welle

AISI420, AISI316

Dichtring

EPDM, NBR, Silikon, Viton, PTFE, U-PVC

Temperatur

max. 200°C

Einbaunorm

PN10/16, ANSI Class 150

Normen

EN-558 Serie 20 (DIN3202-K1), ISO5752, API609, BS5155

Prüfungen

EN12266-1/2, ISO5208, API598, ANSI B16-104, Class VI

- By akroeze

- March 17, 2016

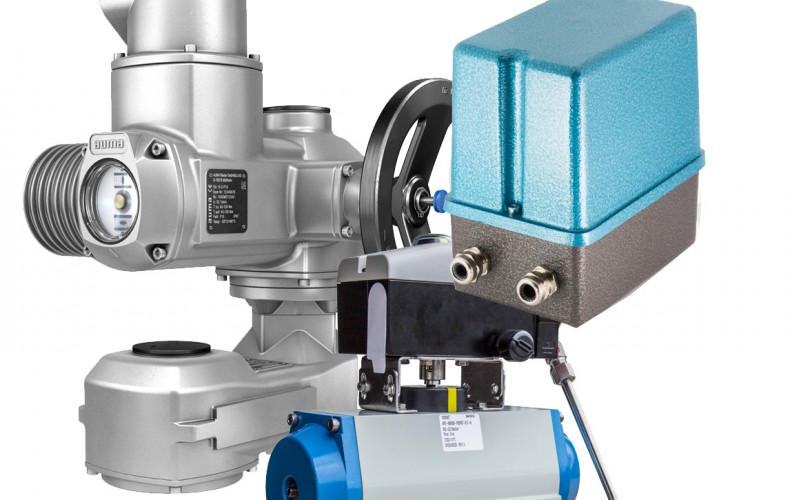

As a systems supplier with extensive experience in the industry, we maintain excellent contacts with all established drive-system manufacturers. We know the market and understand its terms and needs. By choosing Knippenburg Armaturen, you gain immediately access to both our know-how and our everexpanding network. All the synergy effects we generate are passed on to our customers – for mutual benefit. We make sure you get the optimum combination of components (valve – drive – accessories) that are just right for your specific application. And you get everything supplied from a single source. Designed, installed and tested by our experts.

- To contact and terms with all major manufacturers.

- All commercially available operating voltages on stock.

- Running times from 1s to 180 s at 90° movement available

- Torque of 2 Nm to 20.000 Nm, depending on type of actuator

- Positioner and in-/output signal 4-20 mA or 0-10 V

- End position monitoring by using limit switches and torque switches, or by means of mechanical limit switches or proximity switches in a protective box with position indicator.

- Limit switch control – including independent of actuator – through the use of external limit switches or proximity sensors on the valve.

- PU tubing or stainless steel conuits, depending an the application..

- Customized design available on request.

- Emergency manual gear.

- Manual worm gear

- By akroeze

- March 17, 2016

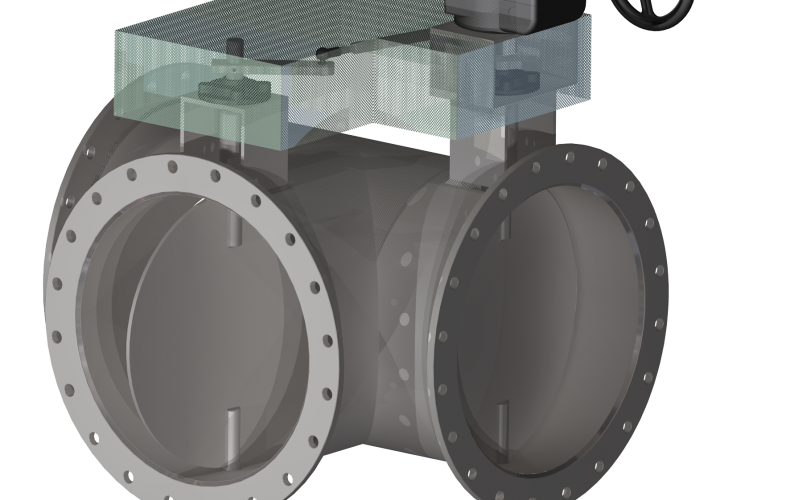

We developed the BEA flange model to serve as a bypass valve. BEA provides a compact regulating system. Customers benefit from its perfectly integrated components. On request, we can also integrate an appropriate blower into the „sealing air“ model. BEA is very flexible in design. It can also be produced as a „diverter damper,” which makes it even more versatile. As with all our products, the BEA is designed with safety in mind and requires very little maintenance. The BEA offers high availability, which serve to ensure processes that are both a profitable and safe.

- By akroeze

- March 17, 2016

The ELA valve was designed to be welded into an existing conduit. When properly installed, it guarantees a 100% airtight connection – without the need for additional sealing material. ELA is therefore able to also regulate and block „critical“ and dangerous media (that should not be allowed to penetrate to the outside). ELA is also the „easy way to regulate air.“

- By akroeze

- March 17, 2016

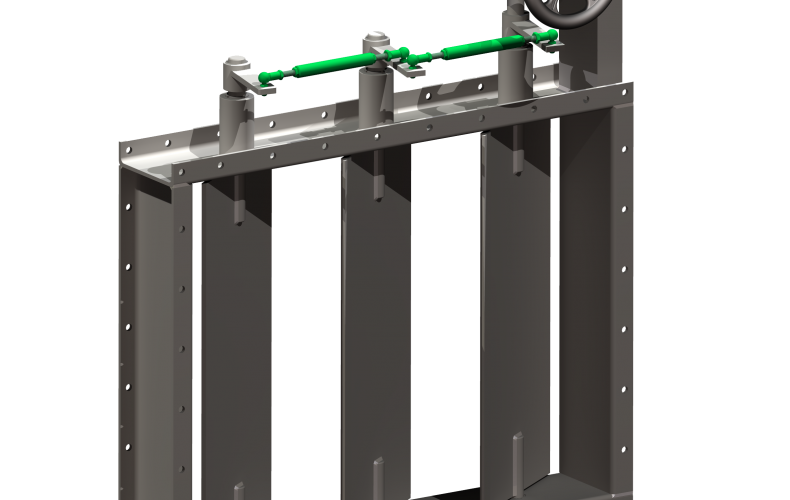

We designed RENA as a single- or multi-vane system. Unless you specify otherwise, they are produced in accordance with the DIN 24193 standard. RENA’s multi-vane system provides better control characteristics and it can be ordered in either a synchronous or asynchronous version. Upon request we can also outfit RENA with a refractory lining made of concrete or mineral wool. The „sealing air“ model is 100% leak-free and therefore completely air tight. As with all our valves, RENA is very robust, low in maintenance and safe. Even under extreme conditions, RENA offers a long service life, very low probability of failure and great reliability.

Other advantages RENA offers:

- Sealing Class I, II, III per FCI 70-2 1976 (R1982) or better.

- The sealing air model is 100% air tight.

- Class I optimized for dust-laden media

- Flange valve with flanges as per DIN 24193 or in specified dimensions.

- DN 50×50 to 2000×2000 DN (other sizes available separately).

- For air, flue gas, waste gas.

- Operating temperatures up to 1050°C

- Low torque due to „low-friction packing.“

- Integrated ISO 5211 interfaces.

- Conversion kit available for easy, subsequent RENA automation.

- Corrosion protection included in the standard model.

- Actuation by hand lever, worm drive, electric, pneumatic, hydraulic

- Fire-resistant lining available (refractory concrete, fireproof mineral wool).

- 100% air tight

- By akroeze

- March 17, 2016

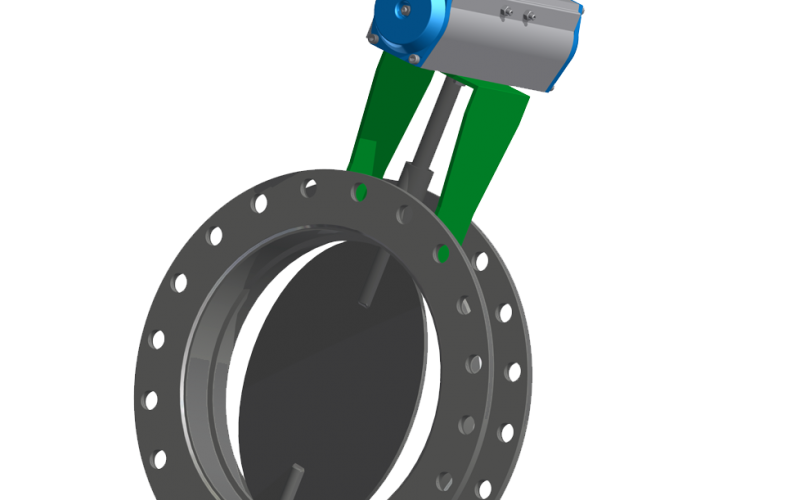

The FINJA flange valve was designed for use in PN and ANSI applications. It is the „big sister“ to our RIA wafer valve, and is in every way equal to the RIA in terms of durability, robustness and safety. Owing to its customized combination of materials and its configuration, FINJA is able to reliably satisfy your every requirement. Like all our valves, we can “automate” FINJA using any drive system commonly available on the market, together with suitable accessories.

Other advantages FINJA offers:

- Sealing Class I, II, III per FCI 70-2 1976(R1982) or better

- Class I optimized for dust-laden media.

- With flanges to clamp between DIN or ANSI flanges

- DIN EN 1092-1 | PN-6 | PN-10 | PN-16.

- ANSI 150 lbs. | 300 lbs. | 400 lbs.

- DN 40 up to DN 2000 (other sizes available separately).

- For flue gas, exhaust gas and air

- Operating temperatures up to 1050°C.

- Low torque due to “low-friction packing”.

- Integrated ISO 5211 interfaces.

- Conversion kit available for easy, subsequent RIA automation.

- Corrosion protection includes in the standard design.

- Actuaton by hand lever, worm gear, electric, pneumatic, etc.

- 100% air tight.